Researchers develop antimicrobial coating from agricultural waste

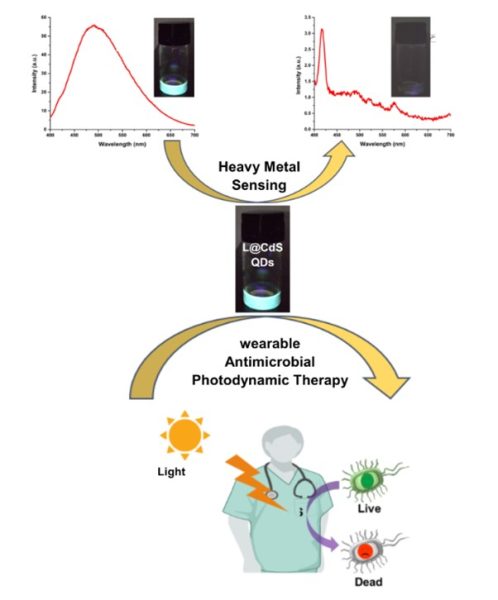

A research team from the DBT-CIAB (Center of Innovative and Applied Bioprocessing), Mohali, has developed a nanocomposite using lignin and nanoparticles of cadmium sulfide called L@CdS QDs (quantum dots).

Further, the team coated the nanocomposite on personal protective equipment (PPE) and demonstrated its efficacy in destroying bacteria.

Lignin is a complex, woody biopolymer that gives mechanical support to plants and helps transport water and nutrients. Post-harvest, lignin is left over as stubble, either burnt or used as cattle feed. However, it is found that lignin is rich in carbon, polyphenols, and antioxidants, besides having antimicrobial properties.

Scientists at DBT-CIAB constantly study ways to develop value-added products from different bioresources.

The present study is an attempt to derive biodegradable nanomaterials for biomedical applications. Biothe team has used green methods to synthesize extremely tiny particles of cadmium sulfide — an inorganic compound — with lignin forming the matrix for the material.

The researchers used kraft lignin for the base material. To obtain the QDs, they added a one-step chemical process to the lignin and incubated the mixture under 365 nm UV light for 24 hours. The reaction yielded 5-nm sized QDs of cadmium sulfide.

It was observed that the nanodots began to glow with a cyan (blue) colour. Noticing this light-triggered fluorescent activity, the researchers performed further tests to validate the photodynamic activity.

Also Read: New study could help fight bacterial infections without antibiotics

The team then standardized and validated structural and morphological parameters of the QDs through spectroscopy and Transmission Electron Microscopy experiments. The test results revealed that the nanocomposite — L@CdS QDs — absorbs energy photons from ambient light and generates reactive oxygen species. Cadmium sulfide nanoparticles absorb light energy and shift to a high-energy excited state. In this state, they react with ambient oxygen molecules and transfer the absorbed energy to them.

The nanoparticles return to their relaxed state while the oxygen molecules absorb the energy and convert to highly reactive ions like peroxides, superoxides etc., collectively called Reactive Oxygen Species (ROS). These ROS are highly toxic to living cells.

Researchers hypothesized that the QDs could act as photosensors to detect microbes when they observed this activity.

The team utilized the photodynamic property of the QDs and performed tests to ascertain the antimicrobial quality. When microbes like bacteria come in contact with ROS, the reactive molecules interact chemically with the microbe’s cell wall and denature or degrade it, thereby destroying the pathogen. “When we exposed the L@CdS QD composite to E coli bacteria, we observed a rapid destruction of the microbe,” said Dr Jayeeta Bhaumik, lead researcher of the study, while speaking to India Science Wire.

Encouraged by the results, the team standardized the nanocomposite and developed it into a coating material for medical equipment. The researchers also simplified the coating process to a dip-coating method. Finally, quantum dots were coated on PPE and medical devices such as masks, gloves and medical tools, and found that it inhibited bacterial growth.

The researchers explain that the lignin base is like bubble gum, and the QDs stick to its surface. The lignin chemicals synergize the antimicrobial properties of the metallic compound. Moreover, lignin acts as a template to stabilize the surface of the QDs, making them non-toxic.

The antimicrobial activity of the nanoparticles can be observed by the quenching of the fluorescence of the quantum dots under 365 nm UV light. When UV light falls on the nanocomposite, it glows with a cyan-blue colour. However, when they interact with bacteria, the glow vanishes.

The researchers have filed a patent for their product. In addition, they are looking for industry partners to scale up the coating production.

The research team included Shatabdi Paul, Neeraj S. Thakur, Sanjam Chandna, Varsha Sagar and Jayeeta Bhaumik from CIAB.

The study results were published in ACS Applied Nano Materials.