- Home

- India

- World

- Premium

- THE FEDERAL SPECIAL

- Analysis

- States

- Perspective

- Videos

- Sports

- Education

- Entertainment

- Elections

- Features

- Health

- Business

- Series

- In memoriam: Sheikh Mujibur Rahman

- Bishnoi's Men

- NEET TANGLE

- Economy Series

- Earth Day

- Kashmir’s Frozen Turbulence

- India@75

- The legend of Ramjanmabhoomi

- Liberalisation@30

- How to tame a dragon

- Celebrating biodiversity

- Farm Matters

- 50 days of solitude

- Bringing Migrants Home

- Budget 2020

- Jharkhand Votes

- The Federal Investigates

- The Federal Impact

- Vanishing Sand

- Gandhi @ 150

- Andhra Today

- Field report

- Operation Gulmarg

- Pandemic @1 Mn in India

- The Federal Year-End

- The Zero Year

- Science

- Brand studio

- Newsletter

- Elections 2024

- Events

- Home

- IndiaIndia

- World

- Analysis

- StatesStates

- PerspectivePerspective

- VideosVideos

- Sports

- Education

- Entertainment

- ElectionsElections

- Features

- Health

- BusinessBusiness

- Premium

- Loading...

Premium - Events

Canadarm: A handy arm in space that will build a house on the moon

A heavy lifter robotic arm in space, Canadarm is all set to build the lunar gateway or a space habitat on the moon, just like it built the ISS.

When doing heavy physical work, an extra pair of hands is always welcome. And as the elders would say, the brawnier, the better. Four decades ago, when the US’ National Aeronautics and Space Administration (NASA) was planning space missions, the Canadian Space Agency (CSA), which had been associated with it in robotics since the 1960s, came up with a heavy-lifter crane, more of a robotic...

When doing heavy physical work, an extra pair of hands is always welcome. And as the elders would say, the brawnier, the better.

Four decades ago, when the US’ National Aeronautics and Space Administration (NASA) was planning space missions, the Canadian Space Agency (CSA), which had been associated with it in robotics since the 1960s, came up with a heavy-lifter crane, more of a robotic arm called the Shuttle Remote Manipulator System (SRMS), for carrying out heavy tasks in space.

The SRMS took to the skies in November 1981 on Columbia’s second mission, the STS-2. It soon became a permanent fixture on the space shuttle and also on the International Space Station (ISS). Renamed as Canadarm, it has flown on 90 shuttle missions in the last thirty years.

Now, Canadarm 3, the latest version of the robotic hand, modified to suit the working conditions of deep space, will soon fly to the moon and start building the lunar gateway or a space habitat on the moon, just like it built the ISS.

The Canadarm 3 will operate on auto mode at the moon outpost, as sending humans is a costly affair until the habitat is ready.

As good as a human arm

When it was conceived, the arm’s premise was to enable the shuttle expeditions to haul heavy payloads in space and perform risky tasks beyond astronauts’ reach. And the Canadarm, visualised like a human arm, just did it, much better than the latter.

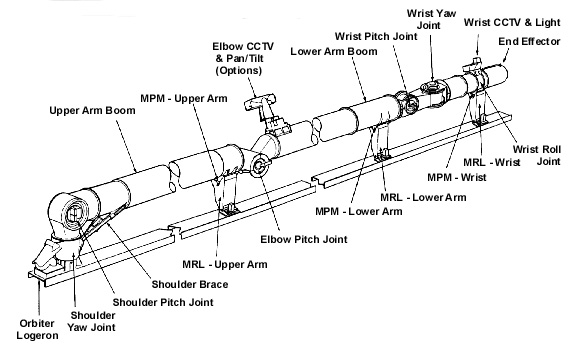

It has a long, 15m arm, with six joints having a shoulder, elbow, and wrist, and with one-degree freedom of movement (movability in ways and directions), making it more flexible than a human arm.

Cameras positioned at the elbow joints and wrist form the guiding eyes as the arm rotates and twists to perform extraordinary tasks in space. The joints move through 270 degrees in each direction (giving an overall 540-degree span).

A sequence of onboard computers forms its brain and sends it commands for tasks to be done. The signal is given only after integrating the operator’s inputs.

The feedback is so thorough that Canadarm works with high precision at a fine range of speeds — between 30 cm and 1.5 cm per second (depending on the load) and can haul weights as heavy as 115,000 kg or sometimes more, and place them within 5 centimetres of the target position.

In 2011, the Canadarm 2 received an additional palm-like dextrous hand called Dextre to grab objects. Sensors fitted to the hand give the arm extra sensitivity and grip.

Taking on more responsibilities

In the late 90s, the Canadarm was instrumental in assembling the ISS, module by module, and building it to what it is today, a space habitat for humans for the past twenty years.

Although NASA grounded the space shuttles in 2011, the Canadarm stayed. Having been suitably upgraded to Canadarm 2, the robot had become a permanent fixture on the ISS since 2001.

Instead of its earlier fixed position, the Canadarm now has guide rails on the ISS for extended mobility. Capable of traveling end to end, it can reach many inaccessible parts of the habitat, further enhancing its tasks.

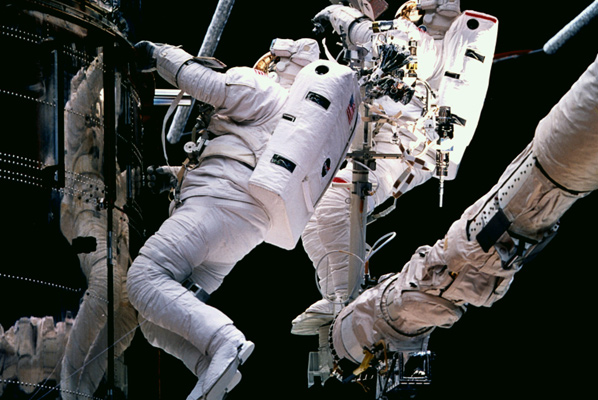

The arm has effortlessly performed repairs and maintenance, carried and guided astronauts during spacewalks, and adjusted satellites’ course. It has also facilitated the repair of the Hubble Space Telescope and retrieved wayward satellites. The arm routinely scrapes off ice growths off the exterior of ISS and fixes glitches on the solar panels.

The shields and armours

Both Canadarm 2 and 3 are 17 m long, have seven degrees of freedom in the three joints in the shoulder, one at the elbow, and three at the wrist. They can haul nearly 150,000 kilos of bulk in the weightlessness of space.

Dextre, the extended smaller arm, provides additional agility and flexibility to grab and hold objects with finer precision.

While each joint on Canadarm 2 rotates 270 degrees, in Canadarm 3, the rotation is nearly 360 degrees. Also, specialised sensors, called force-moment sensor, give a feel of touch and avoid collisions with space objects.

Canadarm 3 is driven by artificial intelligence and equipped with 3D vision sensors to map its surroundings. Besides, it can self-detach some of its sections for repairs, done inside the lunar habitat.

Thermal sleeves made with advanced aerospace materials like gold-Kapton, dacron, fiberglass titanium, and embedded heaters will ensure the arm withstands the frigid temperatures of deep space.

Looking ahead

Backed by CSA’s cutting edge robotic technology, the Canadarm has established itself in an enviable position in space ventures. CSA looks forward to building a range of robotic arms for different purposes — smaller robots for repairs and maintenance and longer, heftier ones to perform critical space tasks that require proximity of modules.

Above all, CSA plans to expand its frontiers in space by setting up the next generation Canadarm control centre to monitor and integrate all the activities of the Canadarm.

Canadarm has not just proved its mettle in space missions but also spurred several uses on earth. Its technology has inspired robotic surgeries, remote servicing of nuclear power stations and power cables, and cleaning up hazardous, radioactive waste.