- Home

- India

- World

- Premium

- THE FEDERAL SPECIAL

- Analysis

- States

- Perspective

- Videos

- Sports

- Education

- Entertainment

- Elections

- Features

- Health

- Business

- Series

- In memoriam: Sheikh Mujibur Rahman

- Bishnoi's Men

- NEET TANGLE

- Economy Series

- Earth Day

- Kashmir’s Frozen Turbulence

- India@75

- The legend of Ramjanmabhoomi

- Liberalisation@30

- How to tame a dragon

- Celebrating biodiversity

- Farm Matters

- 50 days of solitude

- Bringing Migrants Home

- Budget 2020

- Jharkhand Votes

- The Federal Investigates

- The Federal Impact

- Vanishing Sand

- Gandhi @ 150

- Andhra Today

- Field report

- Operation Gulmarg

- Pandemic @1 Mn in India

- The Federal Year-End

- The Zero Year

- Science

- Brand studio

- Newsletter

- Elections 2024

- Events

What the bangles of Sarethi tell us about glass-making in 200 BCE

Bangles and beads, excavated from various heritage sites, have helped historians to study in detail the amount of creativity and craftsmanship of the ancient people in the making of these stupendous pieces of art. As bangles and beads were easy to wear and carry from one region to the other, they played a significant role in the social and cultural interactions of the ancient people. The...

Bangles and beads, excavated from various heritage sites, have helped historians to study in detail the amount of creativity and craftsmanship of the ancient people in the making of these stupendous pieces of art. As bangles and beads were easy to wear and carry from one region to the other, they played a significant role in the social and cultural interactions of the ancient people. The earliest bangles (made of conch shells), however, are dated to the Neolithic period (from 7000 BCE) at Mehrgarh, a prominent archeological site situated on the Kachi Plain of Balochistan in Pakistan.

Scholars believe that the third and second millennium BCE urban cultures in northwest South Asia and the contemporary Chalcolithic cultures in the rest of the sub-continent have given evidence that bangles were used widely by people during that time. The early bangles, however, were made of materials such as terracotta, shell, stoneware, faience, turtle carapace and copper/bronze and gold. The green and blue-green glazed faience bangles were first made in the third millennium BCE urban cultures of northwest India and continued to be made in later periods until the development of glass technology during the Iron Age.

Terracotta bangles of Mohenjo-daro

A wide variety of glass bangles were produced in the beginning of the early historic period (600 BCE). The popularity of glass increased in the subsequent historic periods, so did the bangles, and they started playing an important role when it came to ornamentation and ritualistic practices. Glass bangles, which are popularly known as choodi, have long been perceived as a ‘social object’ of mass consumption throughout South Asia and they have a socio-ritual status of ethnic identity, according to Alok Kumar Kanungo, who has studied and published extensively on glass and glass-bead production.

The excavation, conducted in Uttar Pradesh’s Sarethi in 2016-17, brought in strong evidence of glass working in the Shunga-Kushana context (200 BCE-300 CE) in the form of a furnace. At least 66 bangles were found during the excavation. Several unfinished and misshaped bangles along with the discovery of the furnace point towards the existence of a local production. However, there was no clarity on how the ancient people in Sarethi managed glass-making. Did they run the show independently?

A team of experts who recently conducted elemental analysis of the glass bangles excavated from Sarethi found an overwhelming presence of the mineral soda-alumina (m-Na-Al) glass types manufactured in India – a possible evidence of local production.

“The dominant glass type at Sarethi, glass type m-Na-Al 8, has been poorly documented so far. It was rarely found outside India suggesting that it was a local production for local use. Although the vitreous material found at Sarethi does not seem to be connected with the process of glass production, it remains possible, based on archaeological evidence, that bangles were made on-site. It is quite likely that the m-Na-Al glasses found at Sarethi originate from a different part of Uttar Pradesh,” says Alok Kumar Kanungo, who conducted the study with Laure Dussubieux and Pushp Lata Singh.

Mineral soda-alumina (m-Na–Al) glass has been found across a vast area stretching from Africa to East Asia, appearing around 500 BC. It is abundant in South Asia, where raw materials to produce m-Na–Al glass are readily available, and was likely manufactured there. However, no m-Na-Al 8 (a dominant glass type at Sarethi) glass has been identified outside India.

The comparison of Sarethi with Kopia, a contemporaneous site 70 km away, shows different glass patterns. At the earliest period, Kopia yielded mostly m-Na-Al 3 glass along with a few other glass types, while at Sarethi, only the presence of m-Na-Al 8 glass was recorded.

“This indicates no exchange of glass occurred during the 200 BCE – 300 CE period between both sites. During the Shunga-Kushana period, the bangle production at Sarethi might have been for local use (within Sarethi and immediate vicinity). The use of m-Na-Al 3 glass at Kopia but also the presence of Roman glass suggest a stronger connection of Kopia with long distance exchange networks, while Sarethi seems to have operated at a more regional level during the earliest period,” write Alok Kumar Kanungo, Laure Dussubieux and Pushp Lata Singh in their paper titled Elemental analysis of glass artefacts from Sarethi (India): Examining possible evidence of glass craft in northeastern Uttar Pradesh, published in Journal of Archaeological Science: Reports, ScienceDirect.

Alok Kumar said glass-making and glass-working are among the early pyrotechnics and chemistry processes applied by humans. “Bead and bangle production techniques encompass a wide range of technologies ranging from simple to highly complex. These technologies developed and evolved through time based on both the creative inspiration of individual craftspeople and the needs to meet the demands of both local and international consumers,” write Alok Kumar Kanungo and Laure Dussubieux in the preface to Ancient Glass of South Asia—Archaeology, Ethnography and Global Connections that they co-edited and published in 2023.

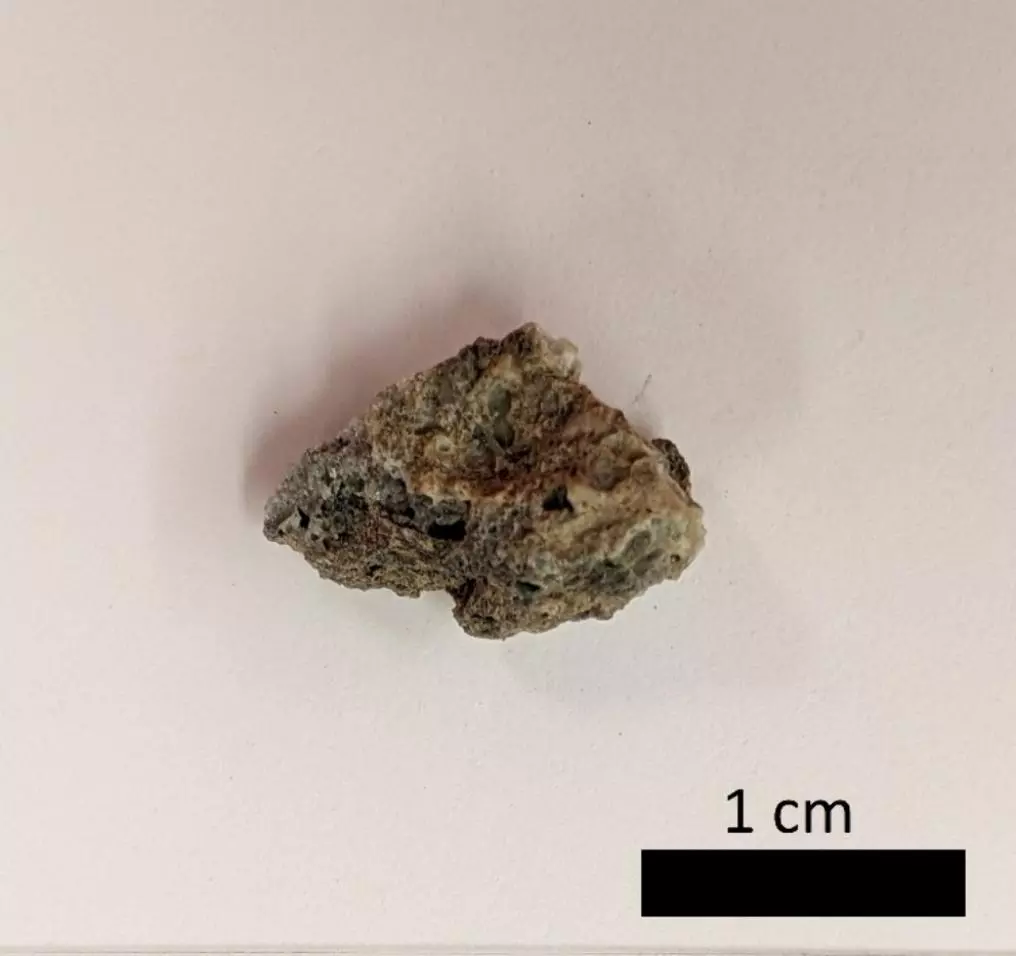

Vitreous material found in Sarethi.

“Beginning with the earliest glass beads dating to more than 3400 years ago at Bhagwanpura in Haryana, furnace wound glass beads have been mastered in North India for 3000 years and furnace drawn beads have been produced in South India for 2500 years. They soon became the most sought-after glass products in the ancient and modern world. These beads and bangles were used by all levels of society as a way to both integrate communities culturally through the use of important symbolic objects and differentiate people by the designs and complexities of production,” they added. Alok Kumar Kanungo is a faculty at IIT Gandhinagar and an adjunct faculty at Flinders University. Laure Dussubieux is a Chicago-based chemist specialise in the determination of the compositions of ancient artefacts made from synthesised or natural glass, metals and stones.

How did ancient men make glass bangles in Sarethi? The ancient people used several methods to produce bangles. Alok Kumar said bangles were made from drawn canes of glass that were shaped into a circle. Their ends were then joined together leaving a seam at the surface of the bangle. A seamless option consisted in forming a bead onto a mandrel. The hole of the bead was then either enlarged by transfer to a clay cone or by using a second mandrel. The shapes of the bangles were modified using various moulds and decorations were designed by applying glasses of different colours onto the blangle’s surface.

As part of their study, the scholars investigated fragments of glass bangles from Sarethi using Laser Ablation Inductively Coupled Plasma Mass Spectrometry (LA-ICP-MS), an advanced technology that helps highly sensitive elemental and isotopic analysis to be performed directly on solid samples. They have identified two main groups of glass: mineral soda-high alumina glass and soda plant ash glass. Although the soda plant ash glass has an unusual composition with no comparanda and an uncertain origin, the mineral soda-high alumina glass (m-Na-Al) is well-known. Why? “It has a composition with high soda and alumina concentrations. A very innovative way to produce this glass, involving a single ingredient recipe, was discovered and implemented by Indian craftspeople. The ingredient, that has different names in different Indian regions, is called more often reh, which combines sand and sodium-rich salts that can be found in areas where rivers draining from mountains contain dissolved salts that percolate through the subsoil until saturation,” they write.

Located in the Faizabad district of Uttar Pradesh, Sarethi not only yielded glass artefacts dating from 200 BCE to 1500 CE but also some possible evidence of bangle-making during the 200 BCE-300 CE period. At least 29 compositions were obtained from the 19 bangle fragments and 11 for the vitreous materials. Some bangles were polychromos and each colour was analysed separately. “Two main glass types were identified at the site, with only one sample with a possible Middle Eastern origin and all the other bangles manufactured from three different subtypes of Indian glass. Most of the tested samples belong to the recently discovered and still poorly documented glass group m-Na-Al 8. The other samples could be attributed to either the m-Na-Al 3 or m-Na-Al 4 glass types,” says the study.

Alok Kumar said the location of Sarethi, a possible glass workshop only 70 km away from Kopia, another contemporaneous glass workshop, brings questions about the glass craft organisation in India and more especially in northeastern Uttar Pradesh during ancient times. “The two sites exhibit distinct glass patterns, more especially at early periods, around the beginning of the 1st millennium CE when, as far as m-Na-Al glass is concerned, only the type 3 is present at Kopia while type 8 dominates at Sarethi. This could indicate that the two glass centres developed independently,” he says. “Sarethi seems to have manufactured glass objects for a very local market. In contrast, Kopia seems to have more long-distance connections. It is interesting to note that the glass found at Kopia belongs to the m-Na-Al 3 glass group, which was found abundantly at sites in Southeast Asia where it was quite likely imported as finished objects and possibly as raw materials,” he adds.

The scholars said no m-Na-Al 8 glass has been identified outside India and although it might be because this glass type was very recently discovered, it might also mean that some workshops (like the ones producing and using the m-Na-Al 8 glass) were dedicated to local distribution while others (like the ones producing the m-Na-Al 3 glass) had a greater access to long distance trade. The study shows how two nearby centres of glass workshops functioned differently when it came to style, design, material and distribution.