Electric vehicle boom comes with battery waste disposal challenge

Jaguar, Mercedes, Tata, Morris Garage, Hyundai and Mahindra have so far launched electric vehicles (EV) is India and many more would come up as the country laps up the environment-friendly mobility movement going on across the world. But are we ready to tackle the potential waste problem caused by the batteries that will be thrown in landfills in the years to come?

Jaguar, Mercedes, Tata, Morris Garage, Hyundai and Mahindra have so far launched electric vehicles (EV) in India and many more would come up as the country laps up the environment-friendly mobility movement going on across the world. The question, however, is are we ready to tackle the potential waste problem caused by the batteries that will be thrown in landfills in the years to come?

There is no doubt a transition from fossil fuels to electric energy was overdue for the automobile industry. The concern about the distant future is how to dispose of the EV batteries once they approach the end of their life. In an attempt to reduce air pollution (caused by fossil fuel burning), are we preparing to pile up waste of rare metals like cadmium, lithium etc while mining more for the same metals?

According to one estimate by the International Energy Agency (IEA), the world today has the capacity to recycle 1,80,000 metric tons of dead EV batteries every year. For comparison, all of the EVs put on the road in 2019 will eventually generate 500,000 metric tons of battery waste. But this is just for a year.

IEA states that by the year 2040, there could be 1,300 gigawatt hours’ worth of spent batteries in need of recycling.

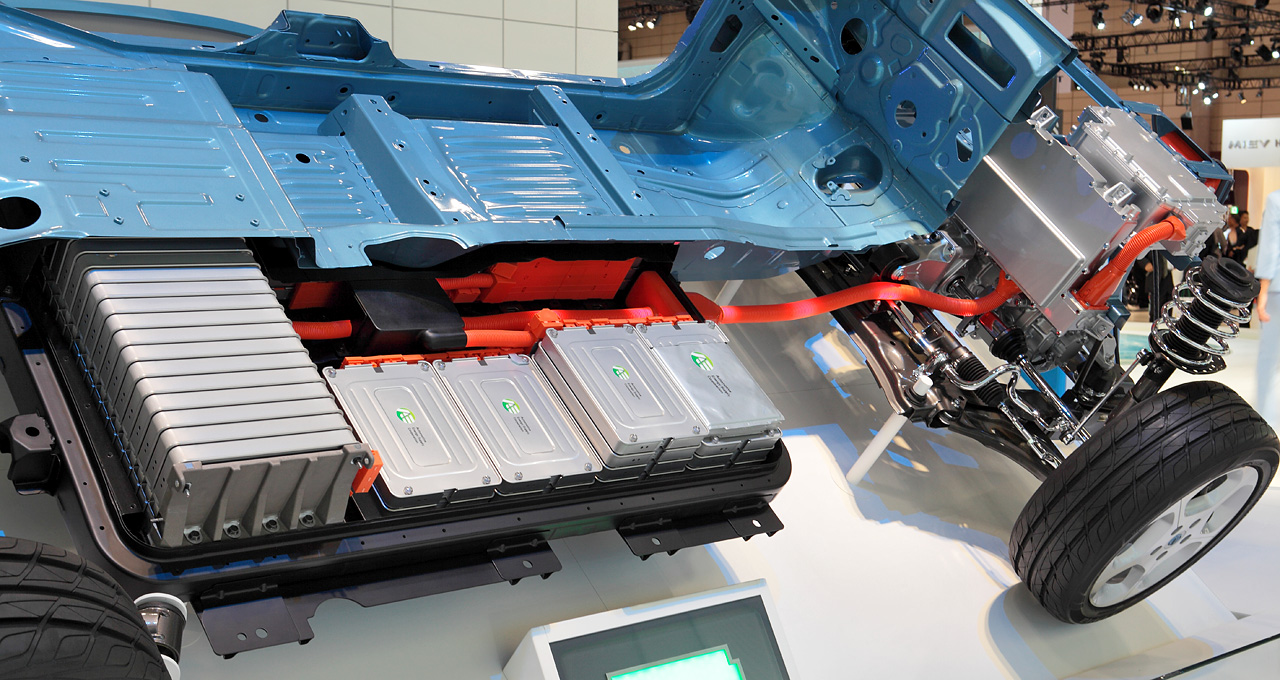

The EV batteries contain lithium, nickel, cobalt and copper among other things. They are rare metals mined from countries like Russia, Indonesia and Congo. These countries have poor environmental control and lax labor standards. And now they are faced with newer challenges like clashes with locals over rights of the miners, their welfare and safety.

The demand for EVs is expected to go up from 10 million in 2020 to more than 140 million by 2030, which means demand for minerals required to make batteries will only increase. So, are we fuelling a dirty mining industry in our quest to shift to clean energy?

The only way to address the problem is to move towards eco-friendly recycling methods for batteries. But EV battery recycling methods employed today are rudimentary, reports National Geographic. The discarded battery’s tough outer casing is removed and modules are thrown in a furnace. Lithium and manganese are burnt, leaving behind an alloy slurry that contains higher-value metals like copper, nickel, and cobalt. Individual metals are then extracted from the alloy using strong acids. All the processes need a lot of energy and emanate toxic gases and waste products.

Cobalt and nickel command high market price and so they are recovered efficiently, but lithium isn’t considered valuable enough to recycle because the quality of the metal recovered is not good enough to make new batteries.

Also read: Increased subsidies for electric two-wheelers a ‘game-changer’

Gavin Harper, a research fellow at the Faraday Institution in the US, told National Geographic, “In the future there might be a cleaner and more efficient option: direct recycling, or separating out the cathode material from individual battery cells and rehabilitating the mixtures of chemicals inside it, including by adding back lithium that has been depleted from use, instead of extracting individual metals from the mix.”

Direct recycling will help recyclers recover more materials from batteries and get a better price for it.

“You’ve got value in the raw materials, but there’s so much more value in the way those materials are combined,” said Harper.

Recycling is not the only way to address EV battery waste problem, but is definitely the most significant way. Scaling up recycling is a sure way of making available most of the minerals required to make new batteries.

IEA says that recycling could meet up to 12 percent of the EV industry’s minerals demand by 2040.

A study by Earthworks concluded that if each and every EV battery is recycled and all minerals, including lithium, are recovered, recycling could meet as much as 25 percent of the EV industry’s lithium demand and 35 percent of its cobalt and nickel needs by 2040.